Practical Magnet Data

Our Story

SuperMagnetMan was born from an idea to marry magnet engineering concepts and solutions with off-the-shelf magnets to meet quick project testing needs. In its infancy, it began to establish its name in the industry with its Founder and Lead Engineer, George Mizzell, teaching and explaining otherwise complicated magnetics concepts online through frequent videos on various topics. This accelerated the company’s notoriety, and it was soon clear that SuperMagnetMan had the expertise customers could depend on for their proprietary design concepts.

Its experience and success with custom magnets lead to an acquisition by Quadrant who transformed the growing potential of SuperMagnetMan into SM Magnetics to foster and develop the custom magnet and magnetic assembly business. SuperMagnetMan remains as the e-commerce brand of SM Magnetics, offering hundreds of ready-to-purchase stock parts online for prototype or production design opportunities.

Our Mission

We believe it is our mission to inspire creativity, fuel innovation, and solve challenges through the power of magnets. We believe in their potential to revolutionize industries, enrich daily life, and ignite curiosity. By offering a comprehensive range of products, we aim to make magnetic solutions accessible for every application.

Why Choose Us?

Engagement

We believe that our store is more than a place to buy magnets; it’s the first step in building valuable relationships. Our team is here to engage with you, understand your needs, and provide the resources and support to help bring your ideas to life. From our wide range of quality products to our personalized service, we are committed to being your trusted partner in magnetic solutions.

Reliability

In a rapidly evolving world, consistency and efficiency are crucial. That’s why we prioritize having an extensive inventory of high-quality neodymium magnets ready for quick-turn delivery. Whether you're developing a prototype or needing parts on-demand, our streamlined process and dependable supply chain ensure that you get what you need, when you need it.

Expertise

Our extensive knowledge of magnetic circuits and experience in various applications drive us to be a solutions-oriented company. We are eager to work alongside innovators, providing tailored products and assemblies that meet the unique challenges of your projects. With our expertise, we aim to support the continuous evolution of your designs and ideas.

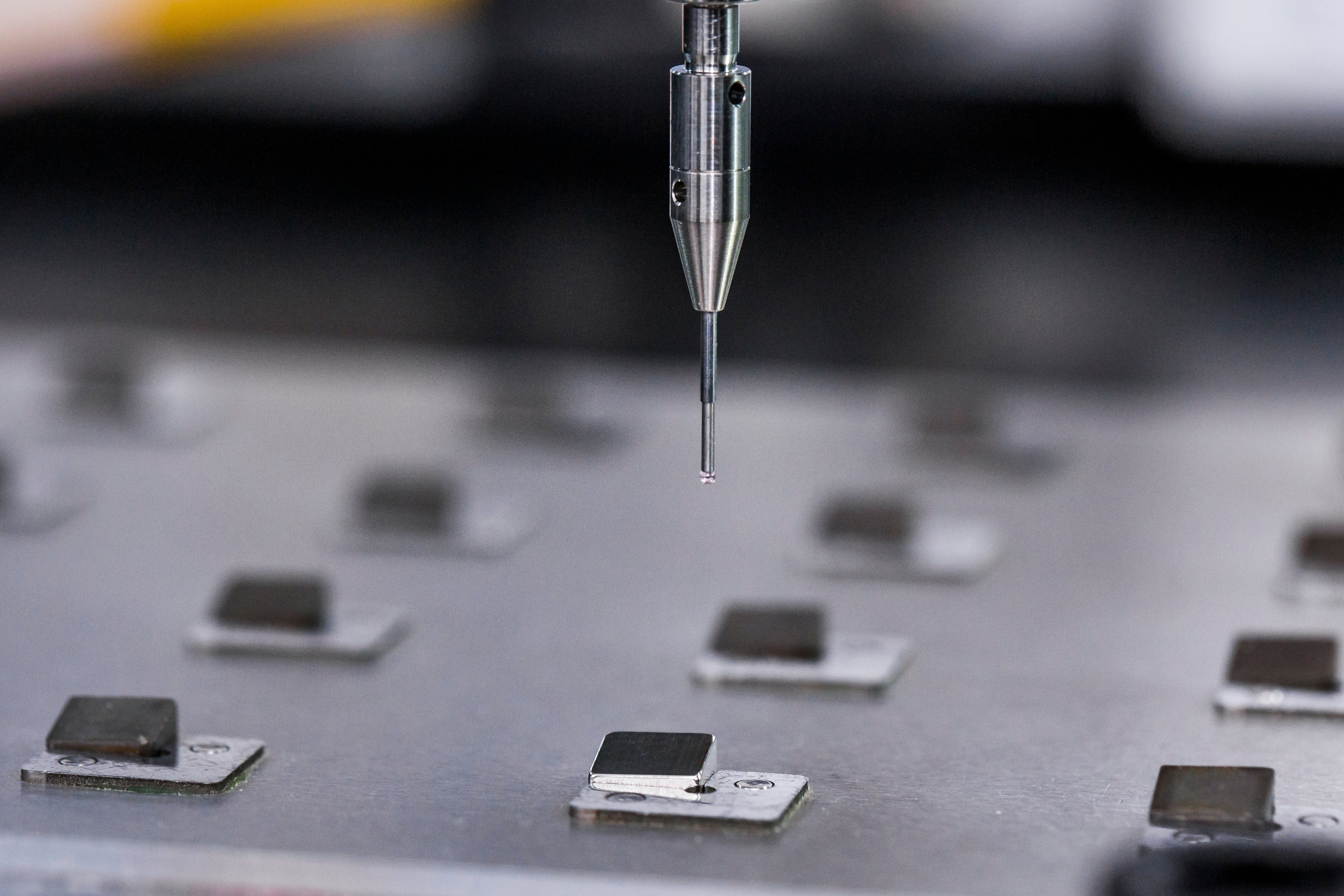

Uncompromising Quality for Unmatched Performance

Quality is at the heart of everything we do. We’re committed to delivering magnets that not only meet but exceed industry standards, ensuring reliability and performance with every project. From rigorous material sourcing to precise manufacturing and thorough testing, our focus on quality guarantees that you can trust our magnets to perform at their best, every time.

Thank you for visiting our website! If you have any questions, feedback, or need assistance, please don’t hesitate to reach out. We’re here to help and look forward to hearing from you!

Contact Us