Additional Resources

Pull Force Calculator

Estimate holding power for your application.

Go to CalculatorCoating Specifications

Compare different coatings for corrosion resistance, and durability to choose the right option for your specific application.

View Coatings NowMaterial Grades & Curves

Explore Neodymium & Samarium Cobalt magnet material specs and BH curves to ensure proper material selection for your specific application.

View Materials NowCustom Solutions

SuperMagnetMan is the e-commerce brand of SM Magnetics, here to make it easy to get the magnets you need for prototyping, testing, or small-scale use. When you're ready for a custom solution—whether that’s a fully engineered magnetic system, simulation support, or a complete assembly—our team at SM Magnetics is ready to help you bring it to life.

About the Product

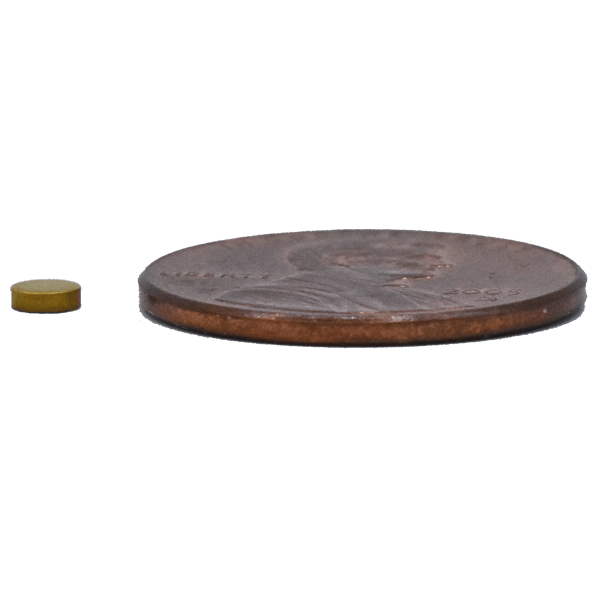

Neodymium disc magnets are a compact, high-energy format used for sensor prototypes, closures, and robotic fixtures. The round footprint seats cleanly in counterbores and adhesive pockets, with consistent thickness tolerance for reliable stack-ups. Standard axial magnetization provides predictable pull to steel. During test-fit, use the Pull Force Calculator to estimate holding force and select coatings appropriate to the environment; consult material data when evaluating grade and thermal behavior.