Oops! The Product You Were Looking For Has Been Discontinued

Oops! The Product You Were Looking For Has Been Discontinued

We're sorry for any inconvenience, but don't worry—we've got you covered! If you're interested in volume pricing or need a custom solution, please contact us and we'll provide you with a quote as soon as possible.

Looking for a Quick Replacement?

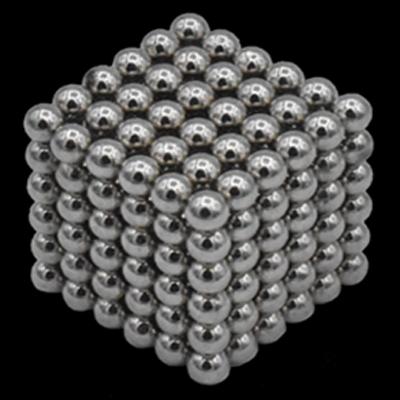

We carry a variety of similar products in stock, and we're confident you'll find a great alternative for your project. Explore our collections below to find the perfect match. If you need any assistance finding the right magnet, don't hesitate to reach out. Our team is here to help!

_

Neodymium & Samarium Cobalt Collections

Magnetic Assemblies & Haptic Motors

Thank you for visiting our website! If you have any questions, feedback, or need assistance, please don’t hesitate to reach out. We’re here to help and look forward to hearing from you!

Contact Us